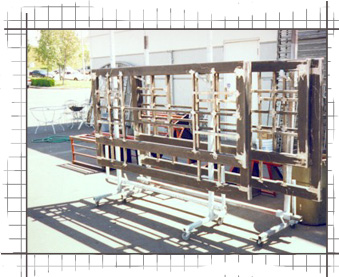

Preperation

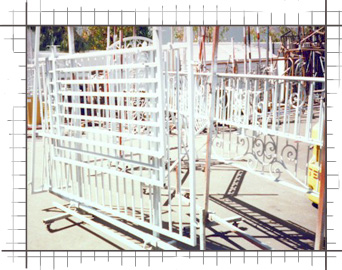

The surface to be treated is first sandblasted. Then wire is fed automatically through the nozzle of the spray gun. A combustible gas, oxygen, and compressed air serve to melt and blow the atomized metal against the surface to be coated. The preferred gas is acetylene although other gasses can be used. For corrosion protection primarily zinc or aluminum is used. Zinc or aluminum, powerful anodes, on steel or iron create a cathodic or galvanic effect that resists corrosion. Rust cannot spread and blister your paint even if the paint, primer, and metallized coating are scratched, all the way through into the iron.